Microwave UV Curing

The next generation

of Microwave UV power and efficiency.

Our Microwave UV Curing Systems use electrode-less, long-life microwave UV bulbs and innovative features to outperform existing UV curing technology in almost every way.

Why Miltec’s Microwave UV System?

At a Glance

Microwave UV Curing Options

Raising the bar for output, energy savings, peak irradiance, reliability, and usability, our Microwave UV Curing line features two power classes—MPI™ is the gold standard in microwave UV curing, while the Xtrema PLUS™ takes the possibilities to the next level.

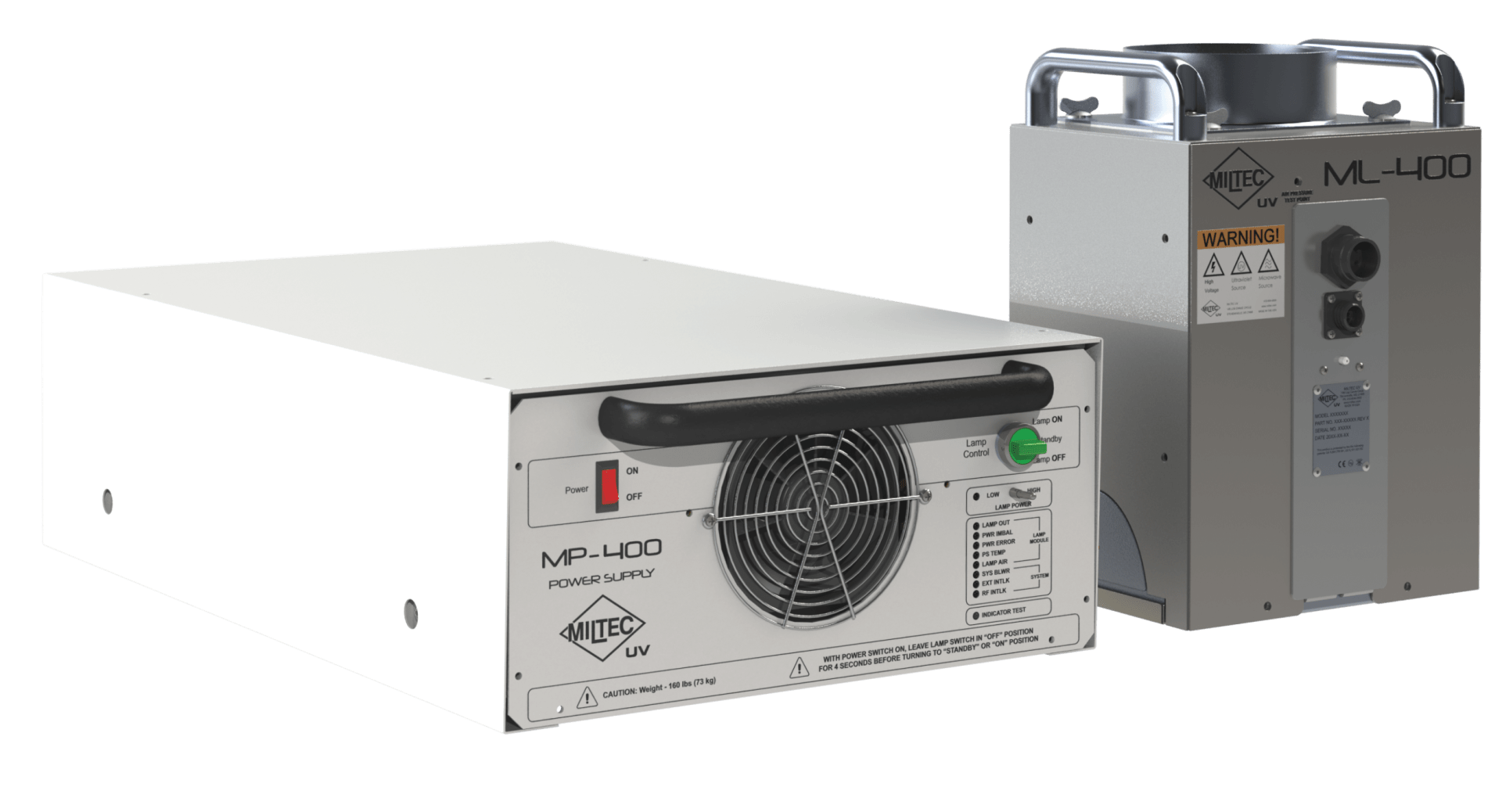

Our original workhorse, the MPI outperforms other higher powered microwave UV systems. At 400 W/in., the MPI outperforms competitors’ 600 W/in. microwave UV systems.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 7.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Maximum energy savings |

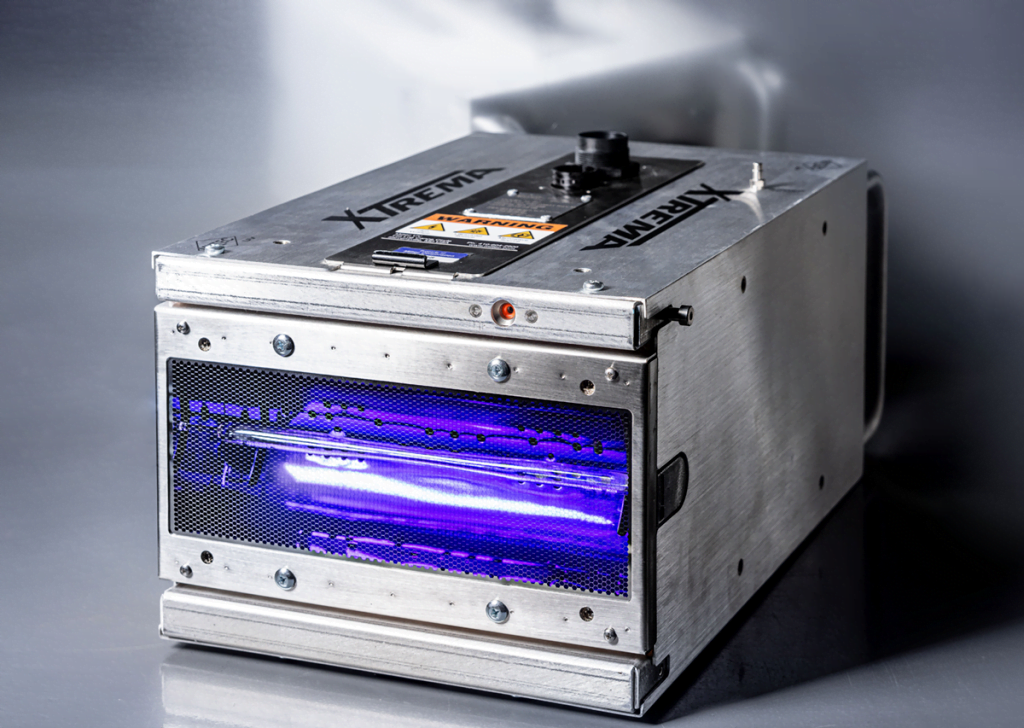

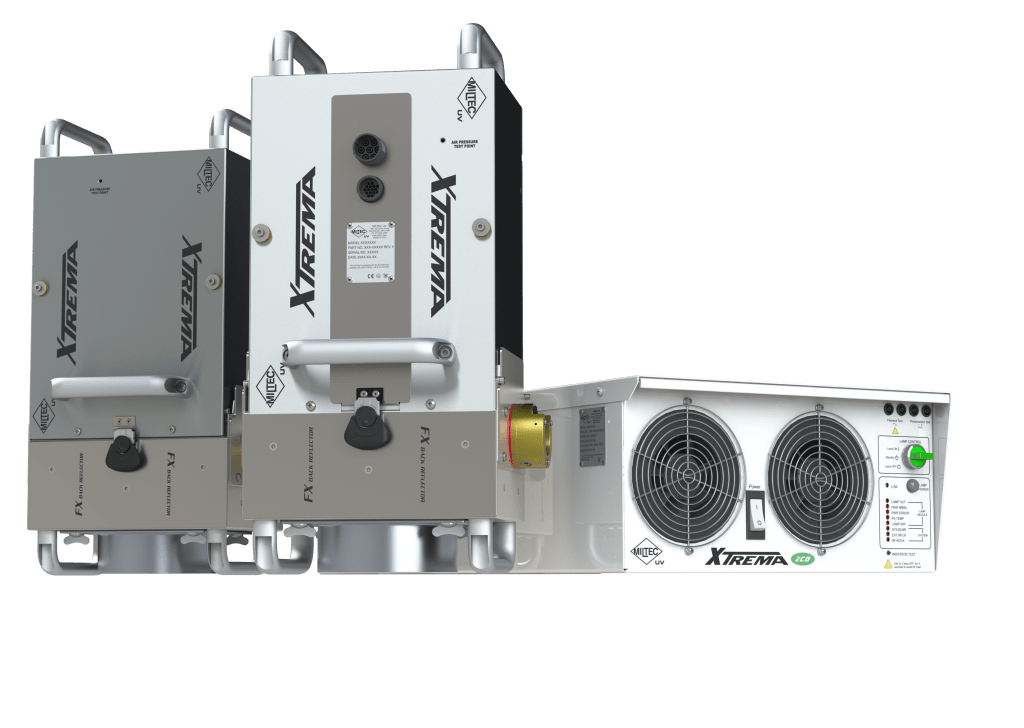

Xtrema ECO simply outperforms other UV systems where it matters most, delivering a peak irradiance that is higher than competitors’ higher powered electrodeless UV systems at two-thirds the electrical energy consumption, saving companies thousands of dollars per year in electrical costs.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 240-480vac (60hz), 380-415vac (50hz) |

| Ideal For Maximum energy savings |

A powerhouse, the 600 W/in. Xtrema Plus offers the highest peak irradiance and superior performance curing UV inks, coatings, stains, and adhesives in a wide variety of applications.

| Watts Per Inch: 236 W/cm (600 W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Faster cure speed, fewer lamps |

What we build

Microwave UV Systems

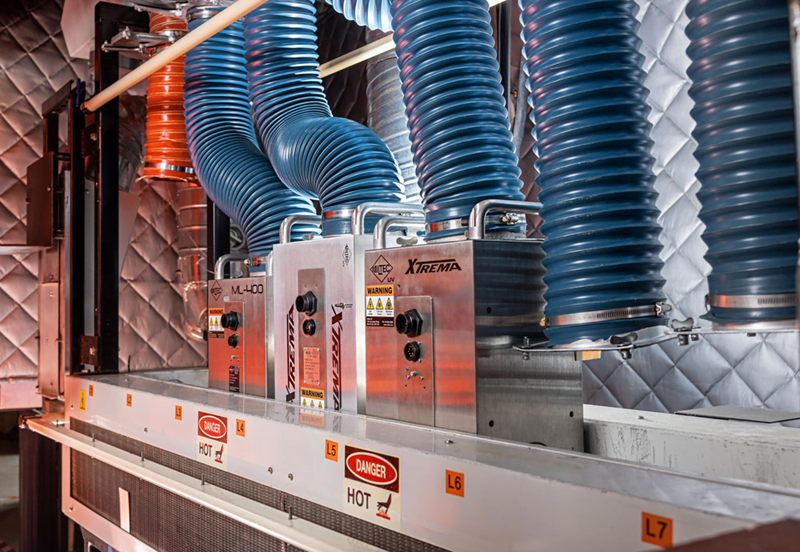

Configured in standalone systems or integrated with almost any existing equipment, we design and build custom systems for applications including but not limited to:

Conveyor & Continuous Web

Easily accessible lamps work on a variety of conveyors and continuous web applications for consistent curing of inks, coatings, and adhesives.

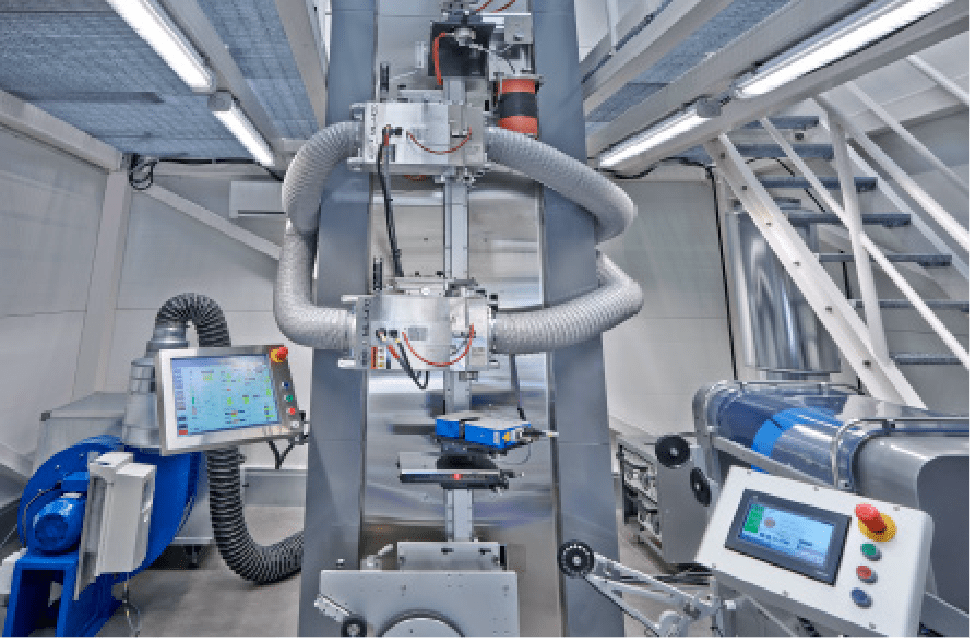

Optical Fiber

Leading optical fiber manufacturers choose our Xtrema ECO for UV curing on draw towers, coloring lines, and FRP coating applications.

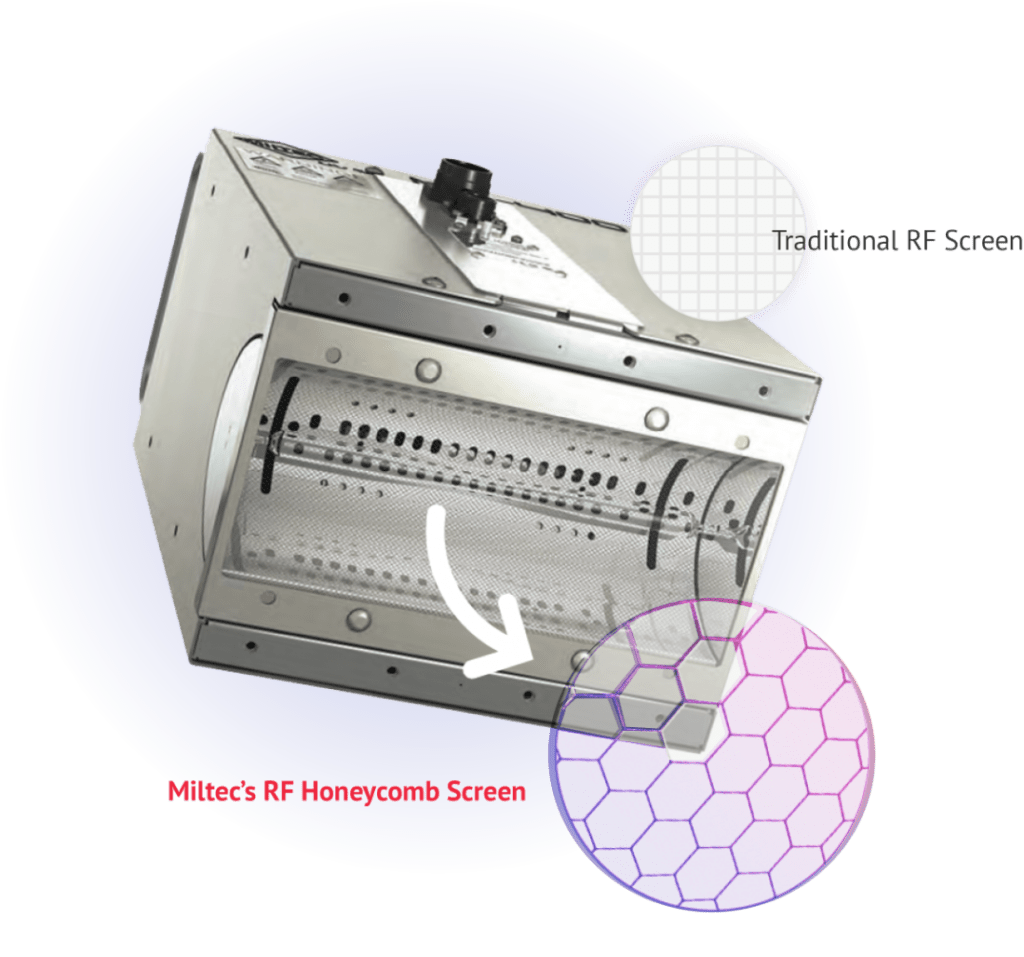

Innovation Spotlight

Innovative technology and thoughtful functionality come standard.

Our innovative ADV Honeycomb RF Screen increases UV light delivered to the substrate, allowing up to 8% higher UV output at the focal point than conventional RF screens. And with our exclusive “quick release” feature, removing and replacing screens on any Xtrema system is a breeze.

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.

Interested in our systems?

Our original workhorse, the MPI outperforms other higher powered microwave UV systems. At 400 W/in., the MPI outperforms competitors’ 600 W/in. microwave UV systems.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 7.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Maximum energy savings |

Xtrema ECO simply outperforms other UV systems where it matters most, delivering a peak irradiance that is higher than competitors’ higher powered electrodeless UV systems at two-thirds the electrical energy consumption, saving companies thousands of dollars per year in electrical costs.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 240-480vac (60hz), 380-415vac (50hz) |

| Ideal For Maximum energy savings |

A powerhouse, the 600 W/in. Xtrema Plus offers the highest peak irradiance and superior performance curing UV inks, coatings, stains, and adhesives in a wide variety of applications.

| Watts Per Inch: 236 W/cm (600 W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Faster cure speed, fewer lamps |

Our original workhorse, the MPI outperforms other higher powered microwave UV systems. At 400 W/in., the MPI outperforms competitors’ 600 W/in. microwave UV systems.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 7.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Maximum energy savings |

Xtrema ECO simply outperforms other UV systems where it matters most, delivering a peak irradiance that is higher than competitors’ higher powered electrodeless UV systems at two-thirds the electrical energy consumption, saving companies thousands of dollars per year in electrical costs.

| Watts Per Inch: 157 W/cm (400W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 240-480vac (60hz), 380-415vac (50hz) |

| Ideal For Maximum energy savings |

A powerhouse, the 600 W/in. Xtrema Plus offers the highest peak irradiance and superior performance curing UV inks, coatings, stains, and adhesives in a wide variety of applications.

| Watts Per Inch: 236 W/cm (600 W/in.) |

| Maximum Cure Width: Unlimited when positioned end-to-end |

| Peak Irradiance: Up to 8.0 W/cm2 UVA |

| Power Supply: 380-480 VAC (60Hz) |

| Ideal For Faster cure speed, fewer lamps |

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย