HPITM Curing Systems

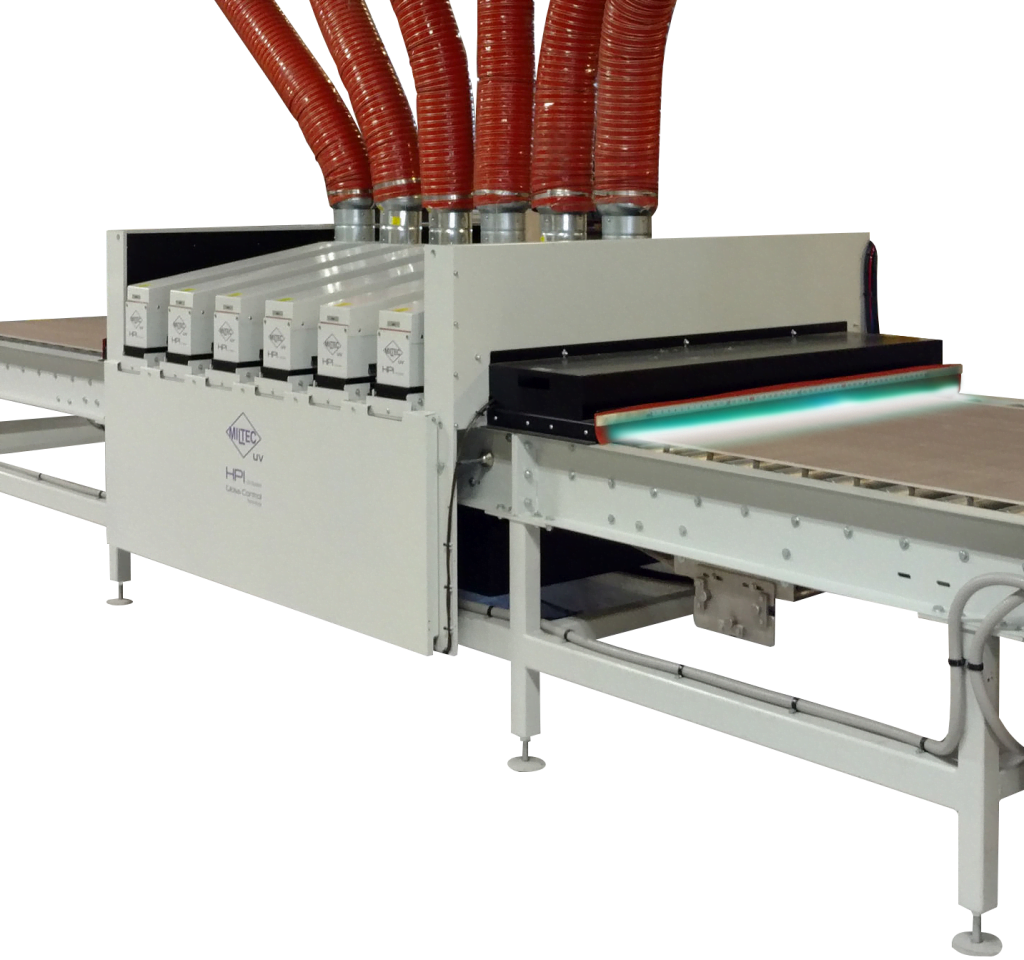

HPI delivers the highest peak irradiance available on the market.

The concentration and intensity of the system leads to better, faster, more efficient UV curing, and makes it the premier choice in industries that demand fast, deep curing of dense inks, stains, coatings, and adhesives.

Capable of achieving up to 2 times higher peak irradiance than other technology—in many cases with fewer UV lamps, HPI’s premium level system offers many features and benefits that differentiate this product from all other UV systems.

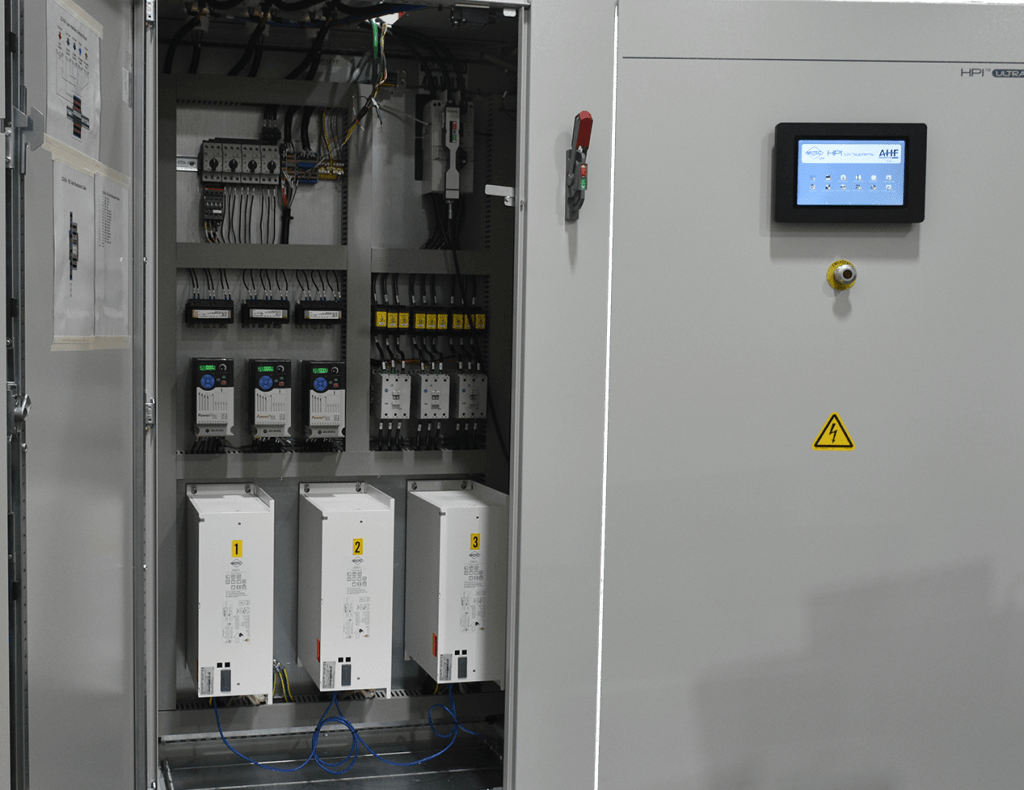

Power Supply

The system powers the Miltec HPI UV lamp housing through an integrated custom cabinet with power distribution, shunt trip main circuit breaker disconnect, ground fault protection, VFD for each cooling blower, and PLC.

The cabinet is cooled with filtered cooling air or an optional air conditioning unit to ensure excellent cooling of the ballasts, which will maximize its lifetime.

Smart Screen Contols

A step beyond the HPI touchscreen with its lamp power/temperature monitoring, and preventive/troubleshooting maintenance, the touchscreen includes:

- Complete system monitoring

- Comprehensive on-screen diagnostics with videos and images to simplify troubleshooting

- Task reminders

- History tracking

- Quick reference lists and schematics

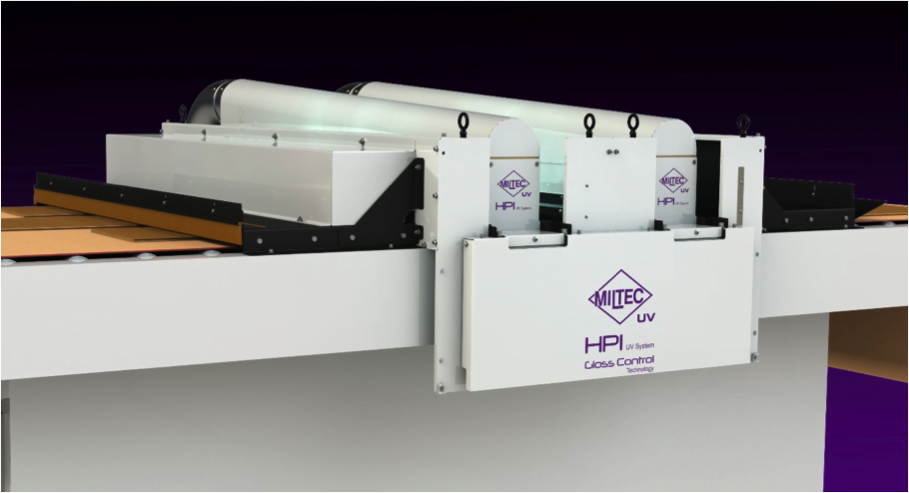

Gloss Control

Of particular interest to flooring manufacturers, UV Gloss Control Technology enables manufacturers to achieve a wide gloss range using a single UV coating. Low, medium, and high gloss levels are easily achievable and repeatable with minor equipment adjustments. This significantly reduces the time spent on chemistry changeovers; saving on downtime and scrap.

APPLICATIONS

The HPI Arc UV lamp system is ideal for larger production environments including:

- Wide web offset printing/coating

- Flat sheet coating/printing on metal, paper, and plastic

- Can decorating – beverage, aerosol, and food

- Bottom rim beverage can coating

- Coil coating

- Wood sheet/flat panel finishing

- All floor finishing applications including: wood, vinyl, LVT, SPC, and more

- Sheet fed off-set printing

- Three-dimensional coating for automotive and plastic parts

- Optical fiber applications

“HPI’s superior air flow and cooling technology eliminated many processing issues we were experiencing with other UV curing systems. And the efficient design and increased UV output helped us improve throughput and reduce waste.”

Mike M., Major Metal Closure Decorator, USA

Request a Brochure

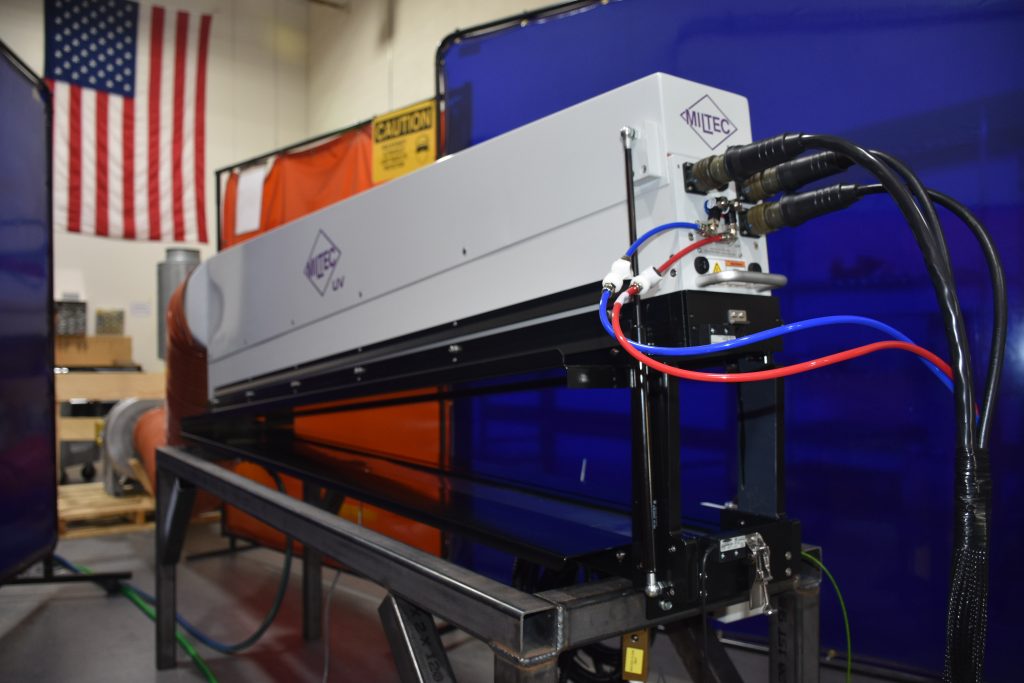

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย