Redefining peak performance.

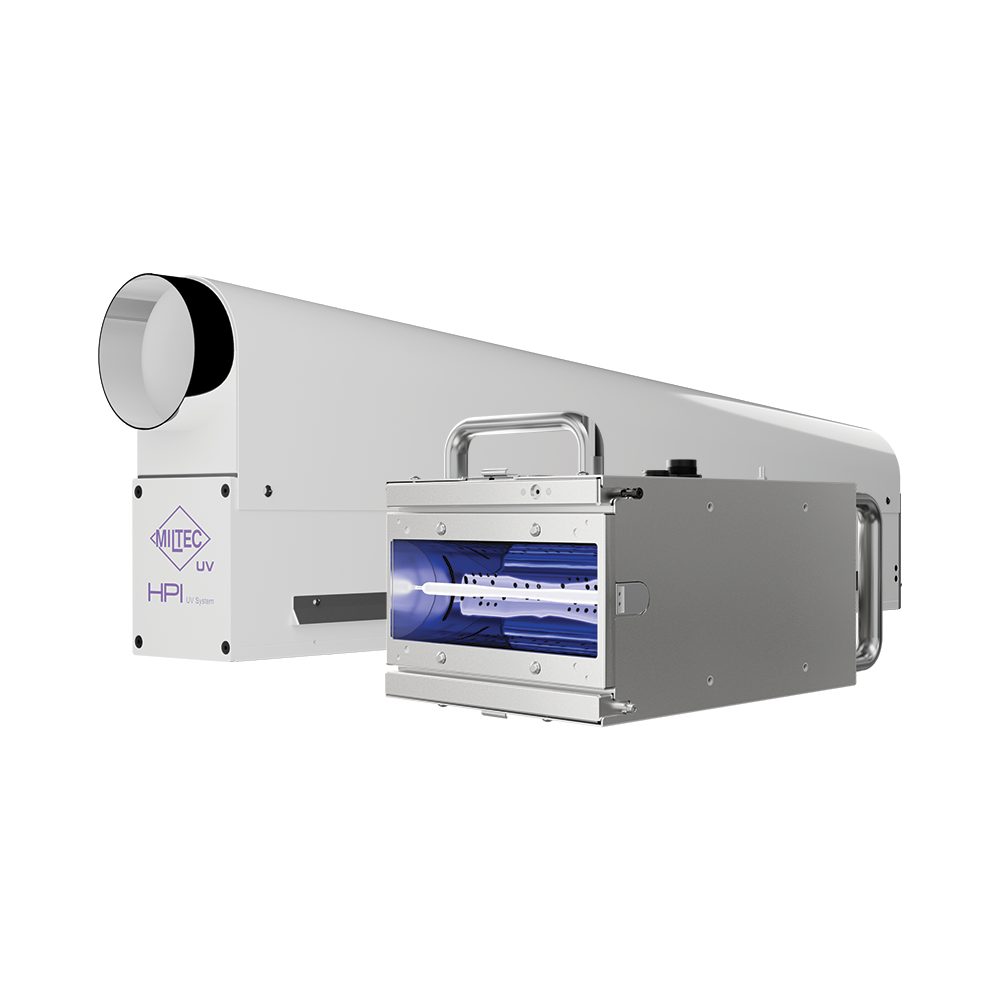

While most of the UV curing industry focuses only on the need for UV energy, we believe that true UV performance depends on both UV energy and peak Irradiance, which is the concentration and intensity of the light. As peak irradiance increases, the UV energy needed to cure an ink or coating reduces. This basic concept allows our high-performance UV curing systems to produce very high peak irradiance UV systems, thus reducing the high UV energy consumption. The net result is a more efficient curing process typically utilizing fewer lamps, fewer spare parts, and ultimately, lowering operating costs.

Peak Irradiance

The intensity of UV output focused on the substrate. Miltec’s UV curing technology achieves up to 2 times higher peak irradiance than typical technology.

Raising the bar.

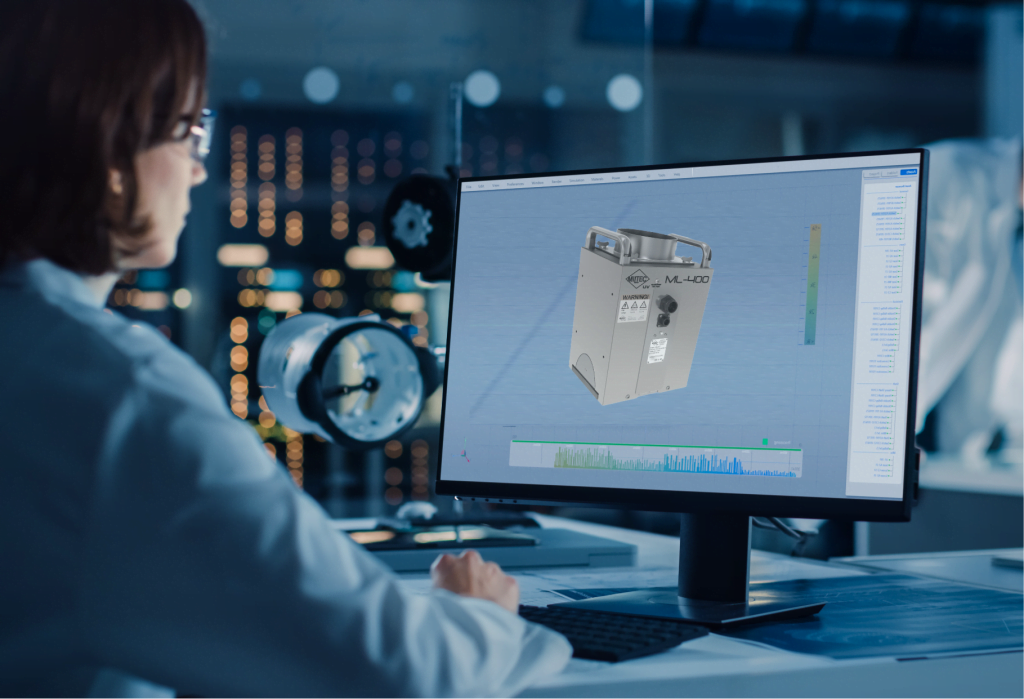

In our fully-equipped laboratory, our researchers, chemists, and engineers develop breakthrough UV curing technologies that yield unparalleled output, performance, and reliability. A few of our innovative technologies include:

- An advanced HPI reflector that uses advanced geometry to deliver maximum optical efficiency and easy removal and installation of reflector liners.

- Quick-release reflectors for microwave-powered UV systems.

- Lithium-Ion battery electrode binder chemistry that can be cured under high-powered UV light and will change the electric vehicle landscape by eliminating the need for NMP, an increasingly regulated solvent.

5

Innovative Technologies

and chemistries

Putting people first.

Innovation is only as groundbreaking as it is usable. From intuitive touchscreen controls to reflectors that can be quickly inspected and removed with minimal production downtime, part of what makes our UV curing technology unique is that it is developed with production operators in mind.

Changing Lithium-ion for good.

Miltec is driving positive change in the rapidly expanding Li-ion battery industry with first-of-its-kind UV chemistries and technology for the manufacturing of separators and cathodes. With an emphasis on protecting the environment and reducing production costs, we are the way of the future in battery production.

Knowledge Center

Sharing. Innovating. Inspiring.

-

UV Curing System

A UV curing system emits UV light to activate photoinitiators in the coating or ink. These photoinitiators generate free radicals that start a chain reaction, causing the material to cure or harden. Advantages of a UV Curing System The primary advantages of curing with UV light are significantly faster cure speeds compared to other comparable…

-

Infrared Round Tube Emitters

Round tube IR emitters are a highly efficient and versatile solution for infrared heating technology. These emitters are designed to deliver exceptional performance across various industrial and commercial applications. This page explores the features, benefits, and applications of Round Tube IR Emitters, demonstrating why they are an optimal choice for anyone seeking effective infrared heating…

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย