What is a Microwave UV System? The microwave-powered electrodeless UV lamp is constructed from a quartz tube containing mercury and a noble gas. It is powered by applying microwave energy to the UV bulb, which excites the mercury into a plasma to produce UV light.

What is UV Curing?

UV curing is the process by which UV light initiates a photochemical reaction of a UV-curable solution (such as inks, coatings, or adhesives) that causes the solution to polymerize.

Benefits of Microwave UV Curing

Electrodeless UV bulbs have a much longer life expectancy than arc lamps. Electrodeless UV bulbs are typically warranted for 6000-8000 hours and can last much longer than that. An arc lamp bulb is generally warranted for 1000 hours of use but will normally last for about 1200-2000 hours.

Electrodeless UV bulbs will perform consistently with little to no drop-off in UV output over their lifetime (assuming the bulb is kept clean). An arc lamp bulb will experience electrode degradation over its use, resulting in a drop in UV output over its lifetime.

Electrodeless UV bulbs will produce significantly less IR (infrared) heat output than an arc lamp bulb because of its smaller diameter. The amount of IR output from the UV bulb is a function of the surface temperature of the UV bulb and the total quartz surface area of the UV bulb. Since both types of UV bulbs operate at virtually the same surface temperature, the smaller diameter electrodeless UV bulb will have much less quartz surface area and produce much less IR output. Less IR output from the lamp is typically viewed as an advantage to the user because it reduces the substrate’s heat load (and temperature rise) as it passes under the UV lamp. It is common for many substrates (such as thin plastic films or plastic parts) to be highly temperature sensitive.

Electrodeless UV lamps do not require shutters for two reasons:

1. The electrodeless lamp comes up to full power in about 15 seconds, allowing for stops and starts of production without significant time delays. If an arc lamp is running and then turned off, it will remain off for a time of 3 to 10 minutes to allow time for proper lamp cooldown and then time to strike the arc when power to the lamp is turned back on.

2. The frequency at which an electrodeless UV bulb is turned on and off will not impact the life expectancy of the electrodeless UV bulb. However, with an arc lamp, increasing the frequency of turning an arc lamp on and off will increase the rate of electrode degradation and shorten the life span of the arc lamp bulb. Consequently, most arc lamp systems will have a mechanical shutter that opens when production starts and closes when the product stops. When the shutter closes, the arc lamp bulb will typically switch to a low power level, and the closed shutter will block the UV light from the process. When the shutter opens, the UV lamp power can switch back to full power almost instantaneously, and production restarts as soon as the shutter opens. Arc Lamp shutters will eliminate production delays when there is a line stoppage and will maximize lamp life.

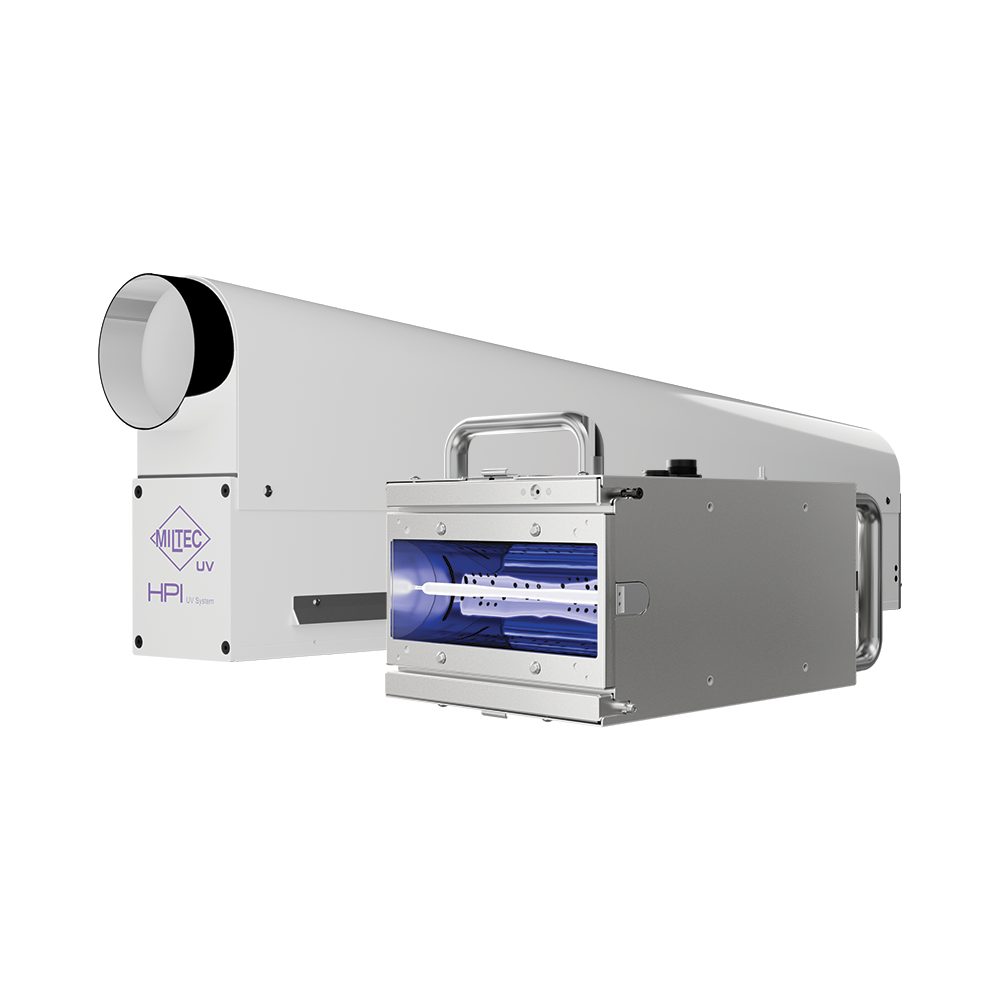

Components of a Microwave UV System

The essential components of an arc UV system include:

UV Lamp Housing Assembly

This houses the UV lamp and includes components such as a reflector and cooling system.

Reflector

The curved reflector within the lamp housing assembly directs UV light towards the substrate, enhancing exposure intensity.

Bulb

The UV lamp emits concentrated UV light with high peak irradiance, crucial for accelerating curing and penetrating UV ink, coatings, or adhesives.

Power Supply

Cooling System

UV lamps operate at high temperatures, and a cooling system is essential to maintain optimal temperature for lamp operation, typically using airflow to dissipate heat and preserve structural integrity.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย