A UV curing system emits UV light to activate photoinitiators in the coating or ink. These photoinitiators generate free radicals that start a chain reaction, causing the material to cure or harden.

Advantages of a UV Curing System

The primary advantages of curing with UV light are significantly faster cure speeds compared to other comparable technologies, such as thermal drying methods. UV consumes much less energy than thermal drying methods, making it more efficient. Typically, UV-curable solutions are made of 100% solids, making this an environmentally friendly technology and negating the need for expensive solvent recovery systems. UV lamps consume much less floor space than conventional drying methods. A typical UV system might consume 5 to 10 feet in the product flow direction, whereas a thermal oven might consume 100-200 feet. UV-cured products can result in a higher quality product, such as higher clarity printed materials.

Components of a UV Curing System

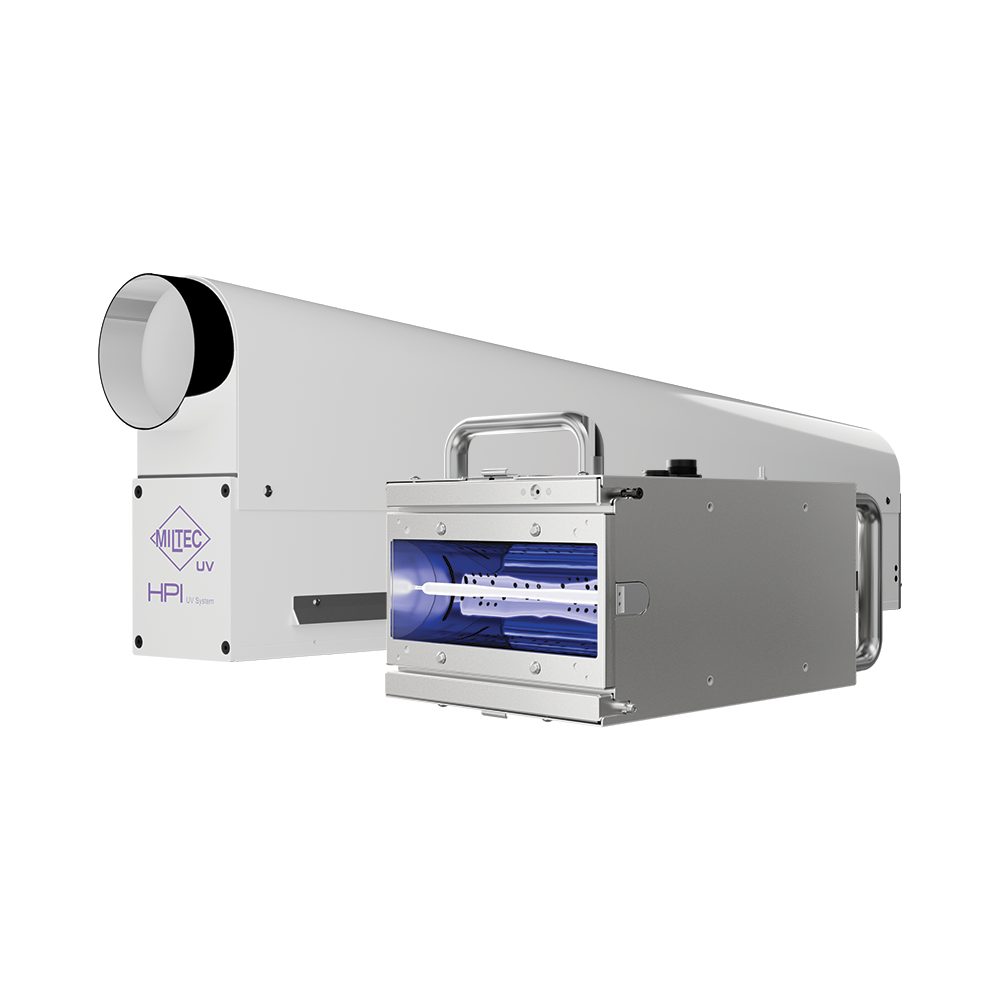

The lamp housing assembly hosts the UV bulb, which is enveloped by a curved reflector that typically spans 50% to 70% around it. A UV curing setup comprises several key components:

- A UV lamp housing assembly

- A power supply (or ballast for arc lamps)

- Cooling System

Lamp Housing

The lamp housing assembly hosts the UV bulb, which is enveloped by a curved reflector that typically spans 50% to 70% around it.

Reflector

The reflector in the lamp housing assembly is curved to align the UV light towards the substrate to concentrate and direct it for intense exposure.

Bulb

A concentrated UV light source with high peak irradiance accelerates curing and enhances penetration into UV ink, coatings, or adhesives. This heightened irradiance facilitates a greater influx of UV photons, enabling more thorough curing through the coating’s depth, which is crucial for adhesion to the substrate.

Power Supply

UV lamp systems typically utilize variable power ballasts, enabling a flexible power output ranging from 20% to 100% of the lamp’s capacity. This extensive adjustment range allows power levels to vary between approximately 130 Watts per inch and around 650 Watts per inch.

Cooling System

UV lamps operate at extremely high temperatures, typically around 800°C or 1,500°F, to sustain a stable, fully developed mercury plasma state within the bulb. Advanced UV lamp setups necessitate a cooling system to maintain the lamp within this temperature range, safeguarding the structural integrity of its surrounding metal components. Using air to blow across the length of the lamp allows the bulb to maintain high output while keeping an optimal temperature.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย