HPITM Curing Systems

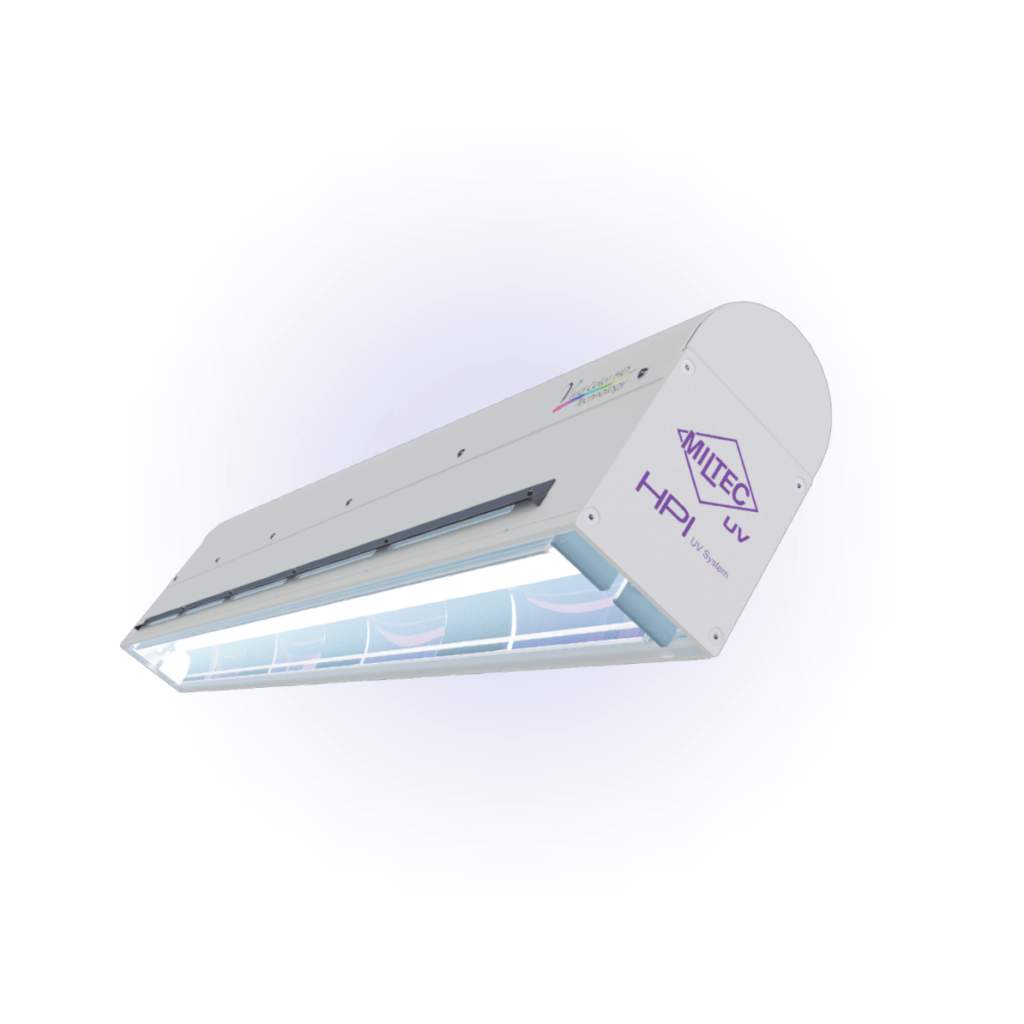

Get unparalleled consistency at virtually any lamp length with HPI XR.

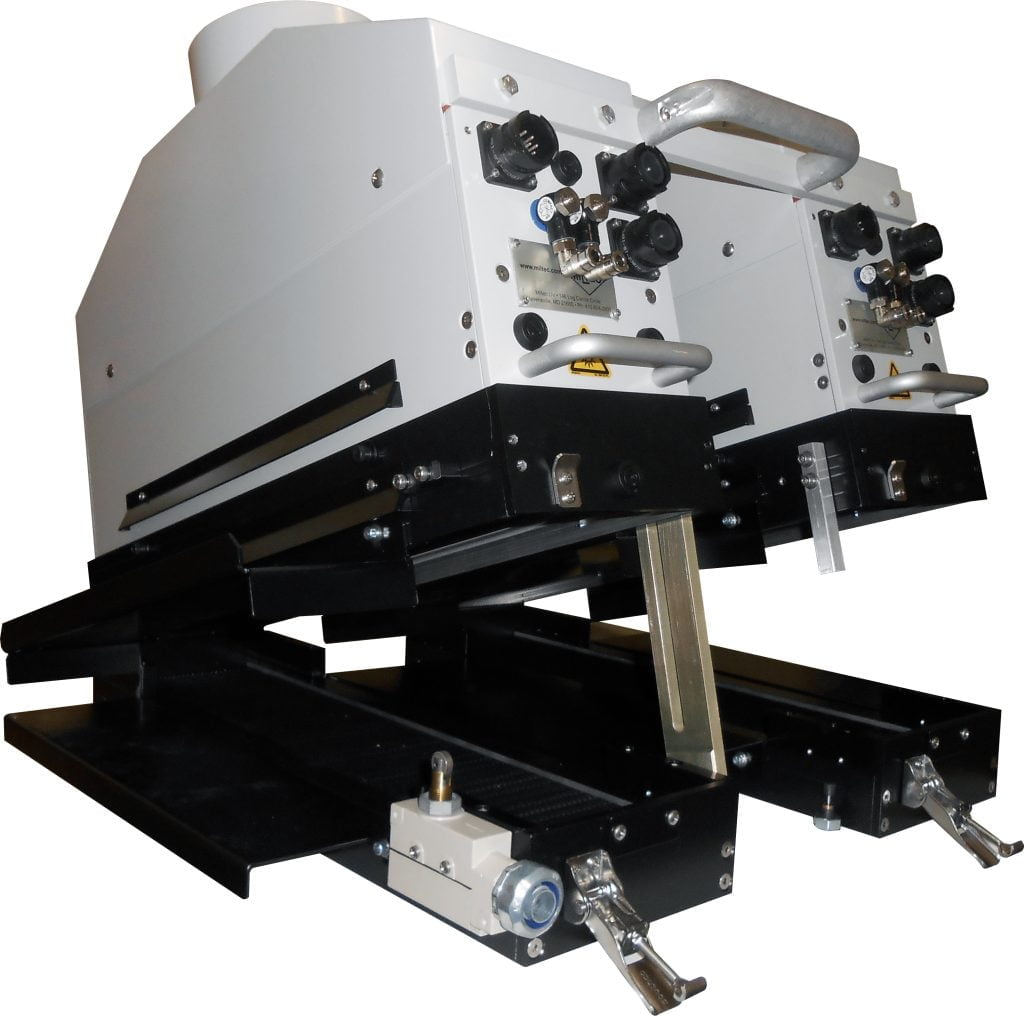

With a compact, modular power supply and the ability to accommodate lamp lengths up to 90 inches, the HPI XR powers up to 650 watts per inch and is adjustable from 20% to 100% power.

The system’s size is ideal for flexible mounting locations and can be configured as a single or multi-lamp system. It’s extremely easy to install and retrofit into any production line with lamps controlled individually or as an automated group.

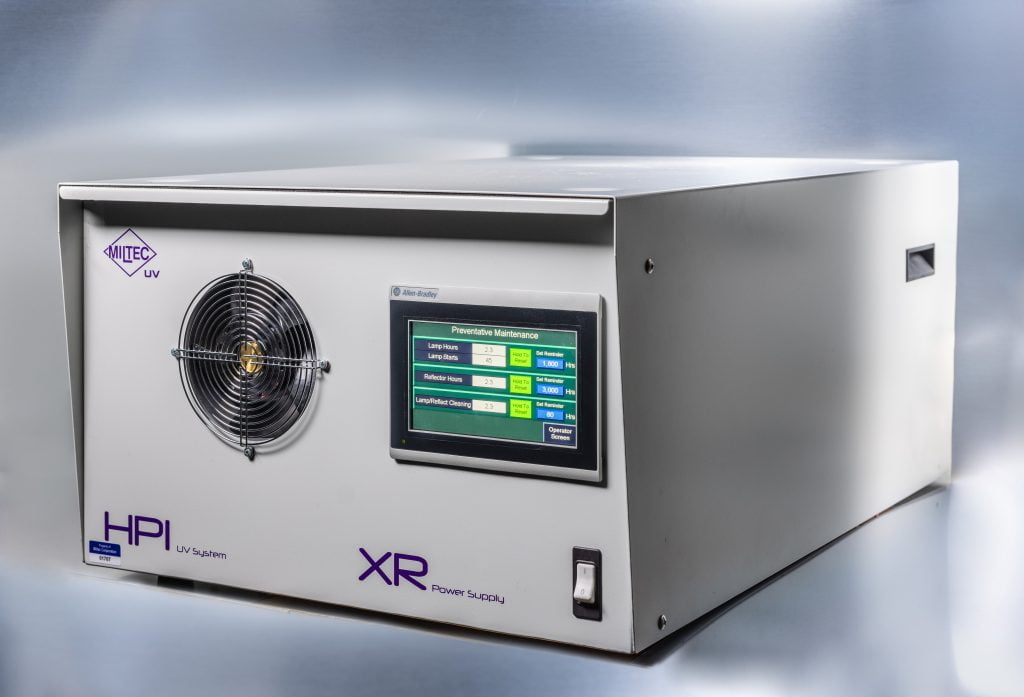

Power Supply

Miltec’s compact XR power supply delivers 98% power efficiency and is available in four configurations, each with a different maximum power capacity. All configurations include touchscreen controls that offer ease of operation, constant display of lamp power and temperature, and troubleshooting assistance.

APPLICATIONS

The HPI XR is ideal for:

- Narrow, sheet-fed, and wide-web offset printing

- Flat sheet printing on metal, paper, and plastic

- Coil coating and bottom rim beverage coating

- Floor finishing applications

- Three-dimensional coating

- Optical fiber applications

“HPI’s superior air flow and cooling technology eliminated many processing issues we were experiencing with other UV curing systems. And the efficient design and increased UV output helped us improve throughput and reduce waste.”

Mike M., Major Metal Closure Decorator, USA

Miltec UV Customer Since 2013

request a brochure

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย