Why HPI arc lamps?

At a Glance

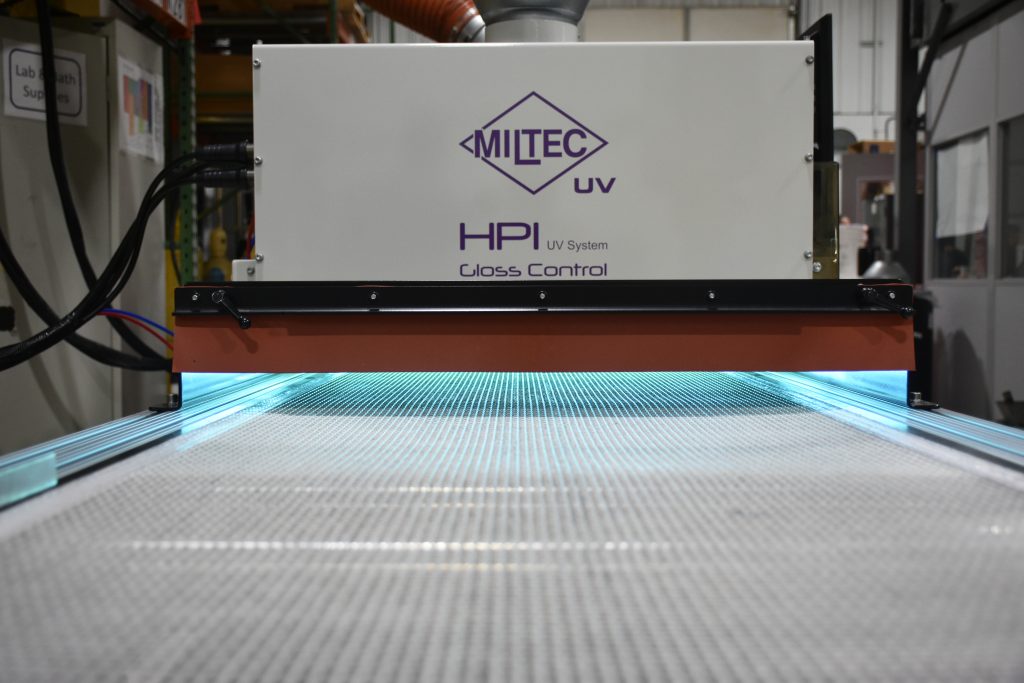

Meet HPI

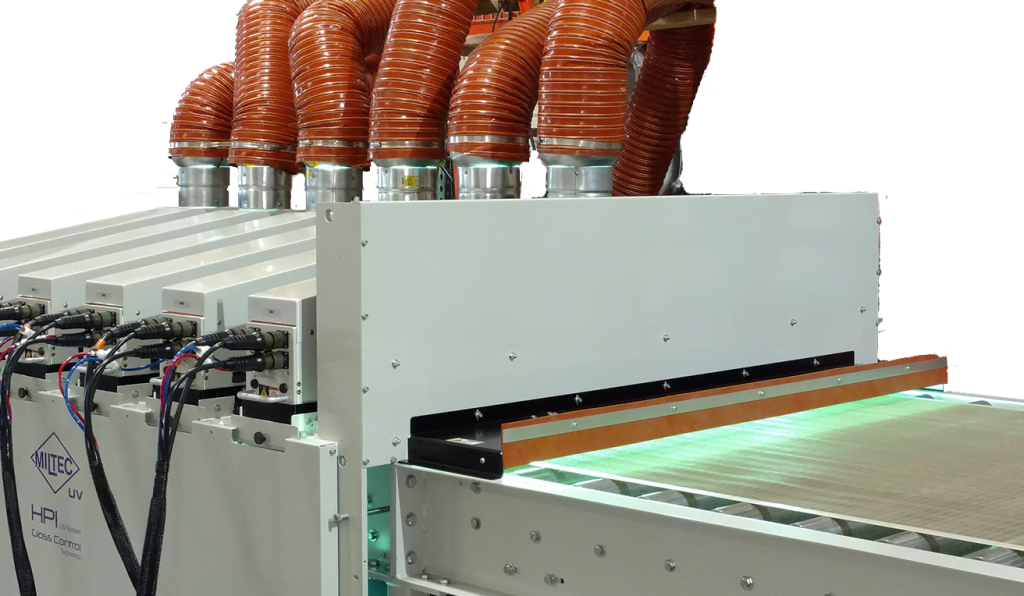

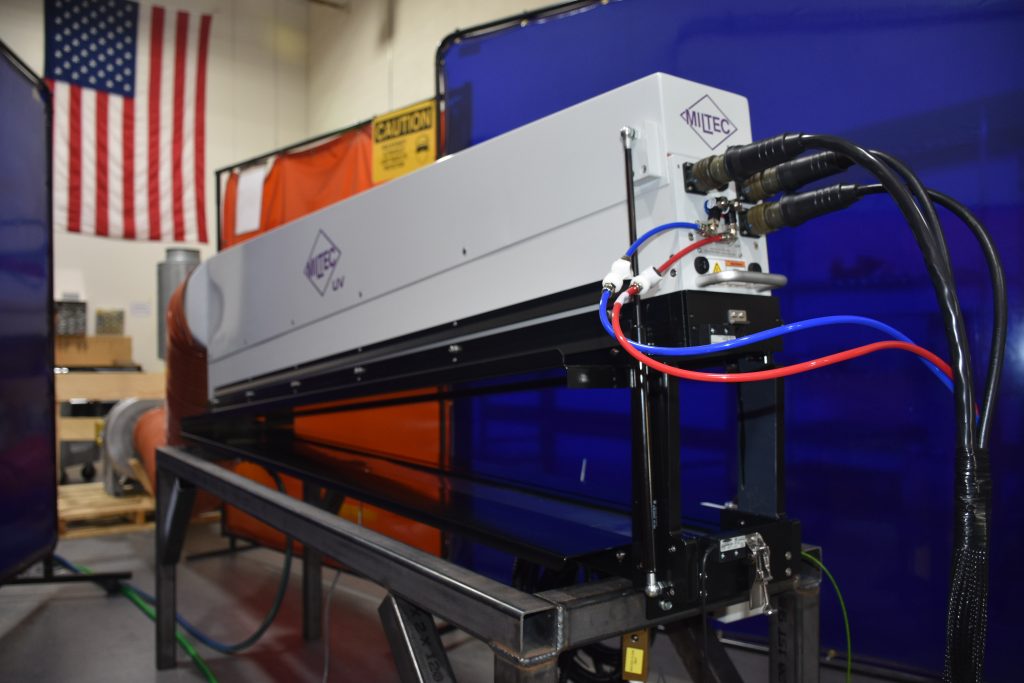

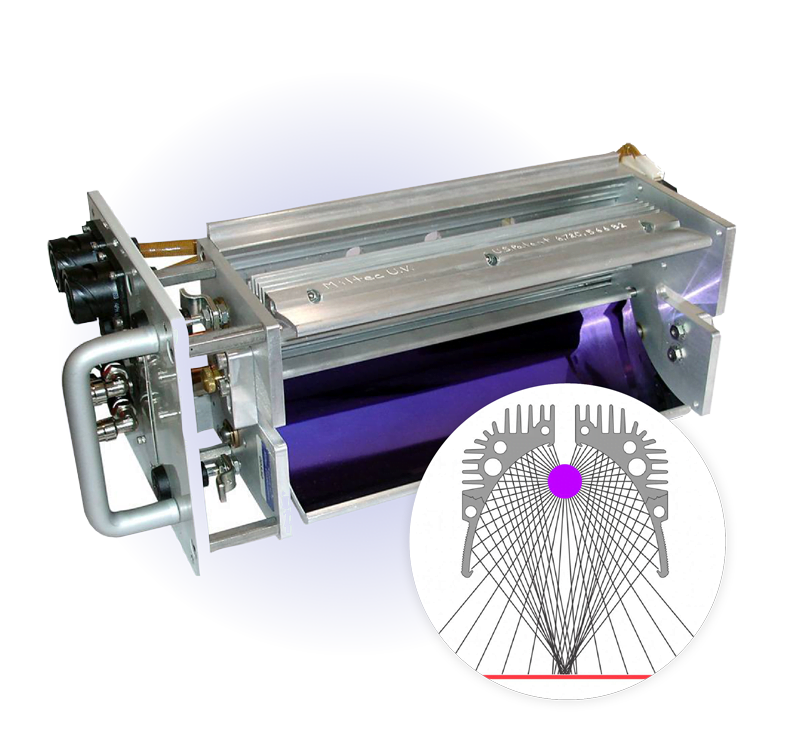

Combining HPI’s extremely high peak irradiance UV output with its unique reflector design and cold mirror technology, HPI arc lamps deliver maximum UV performance with minimal heat load to the substrate. Lamps are available up to 90 inches long.

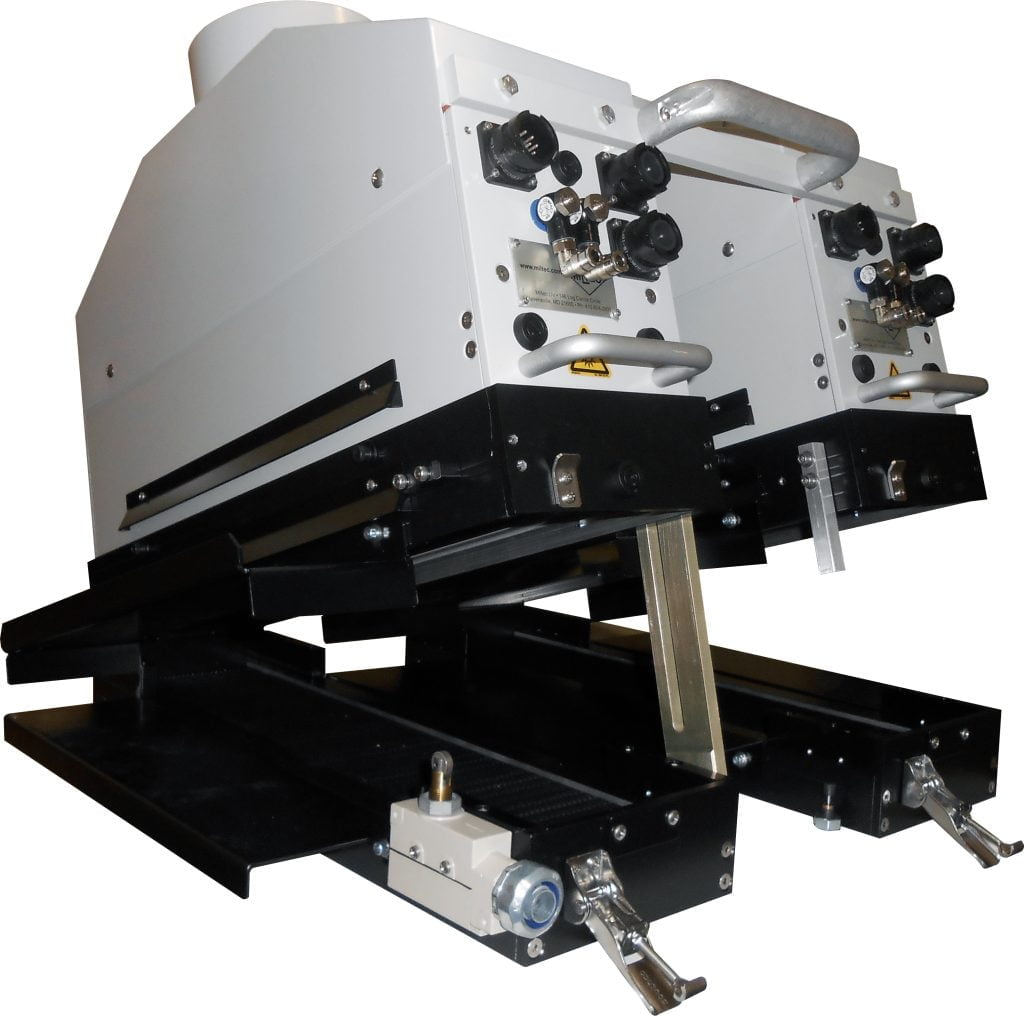

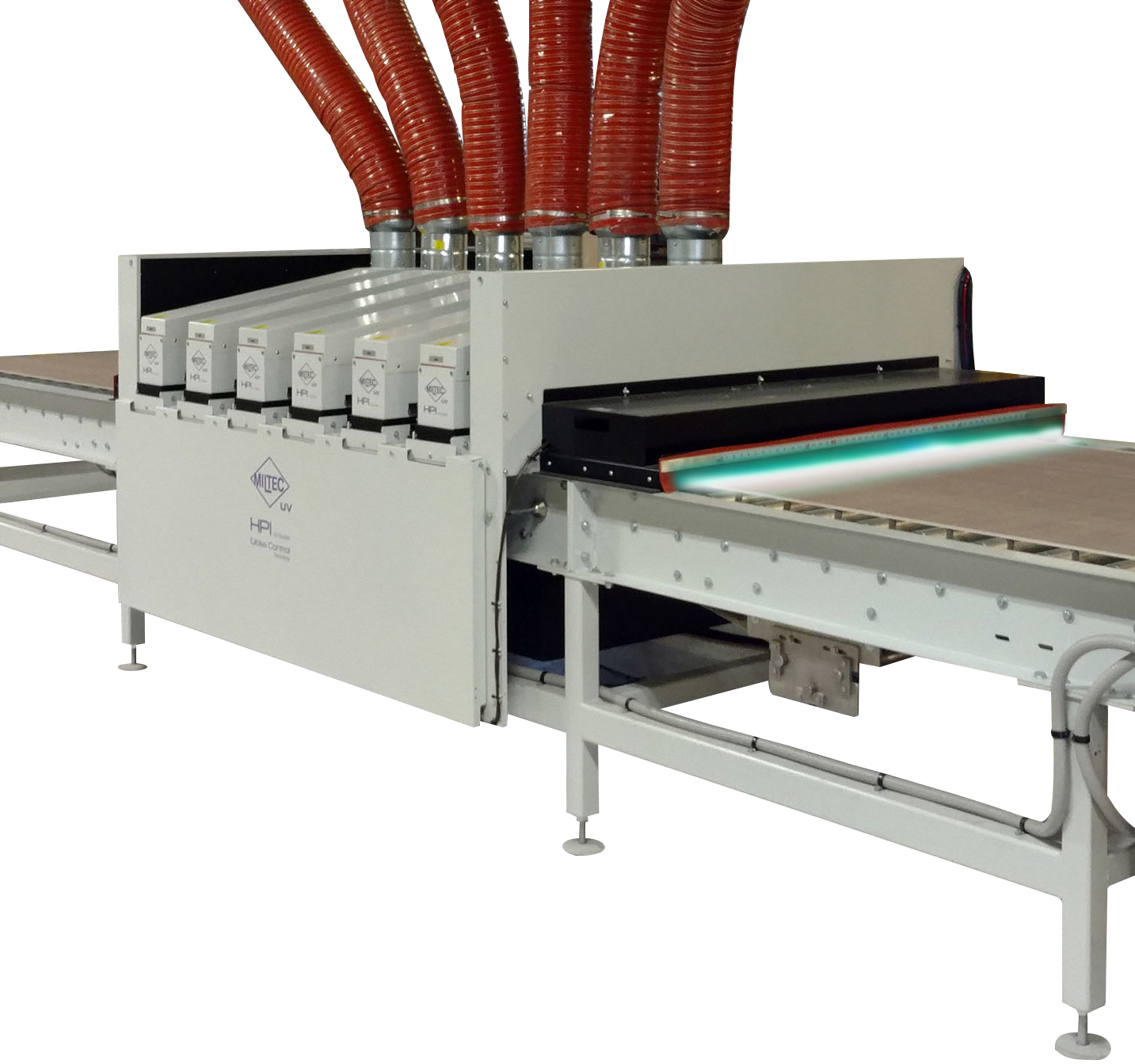

A maintenance-friendly design allows for quick and easy replacement of the UV lamp, reflectors, and other components and the lamp’s compact size makes it adaptable to virtually any application and production equipment.

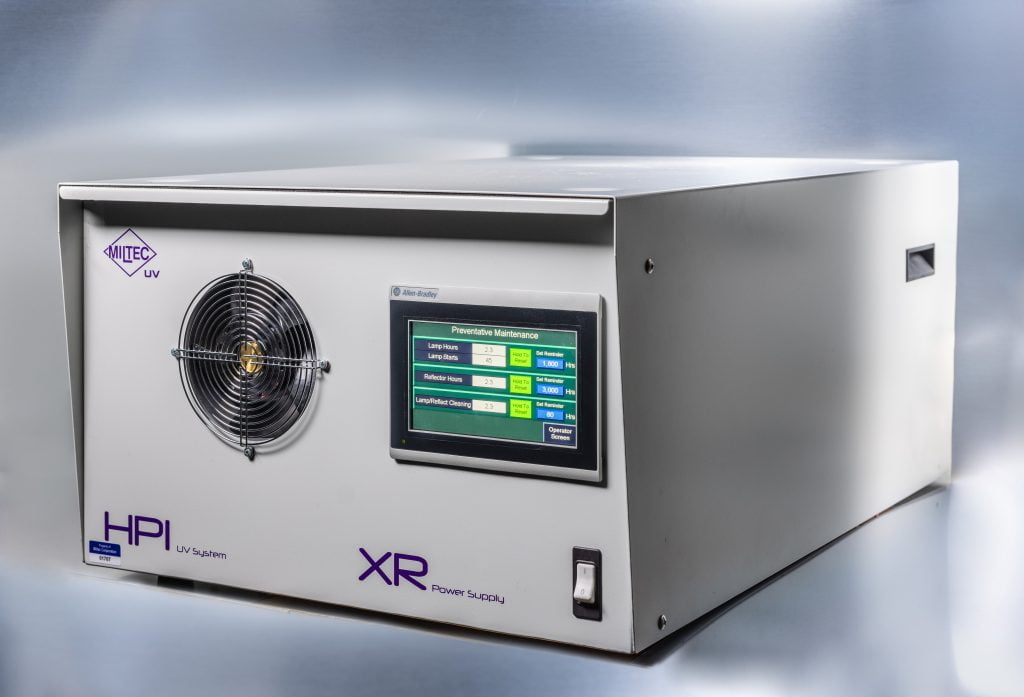

Compact, light-weight, easy-to-install design for up to 15 lamps with 98% efficiency.

The powerhouse of UV systems, the XR offers unmatched production control.

What we Build

HPI Arc Lamp Systems

HPI can be configured in standalone systems or integrated with almost any existing equipment for a wide variety of industries and applications. We design and build custom systems for applications including but not limited to:

Innovation Spotlight

Innovative technology and thoughtful functionality come standard.

Improved optics on HPI reflectors efficiently focus UV light onto the product, creating industry-leading peak irradiance to enhance curing of pigmented coatings and inks. And our patented design allows the reflector liner to be changed without removing the reflector assembly from the lamp housing.

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย